Today, OEMs are facing increasing pressure to streamline production, control costs, and manage complex supply chains — all while maintaining extremely high quality standards. For most industries, this means that simply outsourcing injection molding isn’t enough. Instead, businesses need a full-service contract manufacturing partner that can handle everything from prototyping and molding to final assembly and logistics.

That’s where Ferriot comes in. As a one-stop shop for OEMs, Ferriot goes beyond injection molding to provide comprehensive injection molding solutions, including secondary operations, finishing, assembly, and supply chain support. By consolidating these services under one roof, you can reduce lead times, minimize costs, and improve product consistency while simultaneously simplifying vendor management.

Let’s take a closer look at why full-service contract manufacturing is essential for OEMs looking to scale efficiently and how Ferriot delivers value beyond the mold.

The Challenges OEMs Face Without Full-Service Support

Outsourcing different aspects of production to multiple vendors may seem like a viable strategy, but it often leads to hidden inefficiencies and increased costs. Without a full-service contract manufacturing partner, OEMs encounter several challenges:

- Supply Chain Complexity — Coordinating multiple suppliers for tooling, molding, finishing, assembly, and packaging creates logistical headaches. Every handoff adds risk and delays, miscommunications, and unexpected costs can derail production schedules.

- Quality Control Inconsistencies — When components come from different vendors, maintaining uniform quality and precision across all parts becomes a challenge. Variations in materials, tolerances, and finishes can lead to rework, waste, and performance issues.

- Assembly Inefficiencies — Sourcing molded parts from one supplier and assembling them elsewhere increases the risk of fit and function issues. Misalignments and incompatibilities slow down production and require costly adjustments.

- Rising Costs & Longer Lead Times — Finally, managing multiple vendors often drives up costs due to extra logistics, administrative coordination, and increased shipping expenses. Extended lead times can delay product launches, putting OEMs at a disadvantage in fast-moving markets.

By consolidating these services under one provider, OEMs can simplify production, reduce costs, and enhance overall efficiency. Ferriot’s full-service contract manufacturing model eliminates these challenges, streamlining every step from molding to final delivery.

What Full-Service Contract Manufacturing at Ferriot Includes

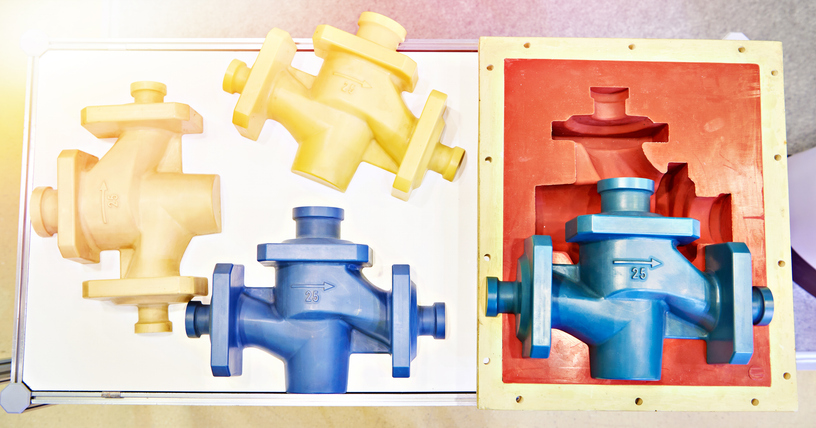

Custom Molding Solutions

Each project is unique, and Ferriot is equipped to provide the most suitable molding solutions for every need. Whether it’s straight injection molding for high-volume, high-precision production, or gas-assist injection molding, which reduces material usage while maintaining structural integrity, we’ve got you covered.

For projects requiring more complex designs, we also offer insert molding and overmolding to enhance durability with metal inserts and multi-material components. Additionally, structural foam molding provides a solution for achieving high strength and rigidity while reducing weight and material costs, making it ideal for applications where both performance and cost efficiency are critical.

In-House Tool Management & Mold Maintenance

At Ferriot, we ensure the long-term performance and reliability of your molds through our in-house tool management and mold maintenance services. We manage programs to ensure smooth transitions during new product introductions and accommodate any tool transfers or insert changeovers.

Our proactive approach to mold maintenance helps minimize downtime, extend the life of your tools, and ensure your production stays on track. We also work with you to maintain a spare parts inventory to quickly address any issues that may arise, preventing unnecessary delays.

Secondary Operations & Finishing

Beyond the molding process, Ferriot provides a wide range of post molding operations to meet both performance and aesthetic requirements. We offer painting, pad printing, and laser marking to add branding or part identification, ensuring that your products stand out in the marketplace.

For more durable and secure assemblies, we provide heat staking and ultrasonic welding to create strong, reliable connections. Additionally, for products requiring protection from electromagnetic interference, we offer EMI/RFI shielding to keep sensitive electronics safe from disruption.

Assembly & Sub-Assembly Services

Ferriot’s assembly and sub-assembly services are designed to meet the needs of OEMs who require integrated solutions. Whether it’s electrical or mechanical component integration, we offer turnkey full service contract manufacturing services to streamline your operations and reduce the complexity of sourcing from multiple vendors.

We handle everything from sub-assemblies to full-scale assemblies, tailoring our approach to your project’s unique requirements. We also employ automation strategies to enhance production efficiency, reduce costs, and ensure repeatable, consistent quality across all stages of assembly.

Supply Chain Management & Logistics

Finally, a true manufacturing partner doesn’t just produce parts — it ensures those parts get to the right place at the right time. With just-in-time (JIT) delivery, Ferriot helps you support lean manufacturing strategies and reduce excess inventory. Our cost-efficient global logistics optimize distribution, ensuring timely delivery while minimizing overhead costs. We also offer inventory management solutions to prevent stock shortages and production delays, ensuring your supply chain remains smooth and uninterrupted.

The Business Impact: Why OEMs Benefit from Full-Service Contract Manufacturing

So what does all of this mean on your end? For one thing, consolidating production processes with a single partner like Ferriot enables you to reduce your total cost of ownership. Instead of managing multiple vendors, which leads to markups and hidden costs, OEMs can benefit from more predictable pricing and fewer logistical challenges.

Time-to-market is another area where OEMs benefit from full-service contract manufacturing. By streamlining the production process under one roof, Ferriot can significantly reduce delays and accelerate production timelines, enabling faster delivery of products to market. This is especially critical in competitive industries where being first can make all the difference.

And finally, with a single partner handling everything, quality assurance becomes much easier to maintain. Ferriot’s integrated approach ensures consistent quality across every stage of production. Our ability to quickly scale production also means that OEMs can meet rising demand or adjust to market changes without facing disruptions.

How Ferriot Delivers Full-Service Contract Manufacturing for OEMs

Ferriot has a long-standing reputation for providing comprehensive manufacturing solutions to OEMs across industries such as industrial, medical, electronics, business machines, telecommunications, and consumer markets. Our experience since 1929 speaks volumes about the trust we’ve built with our clients over the years.

At Ferriot, we go beyond just producing parts: We ensure that every aspect of your product’s development is optimized for efficiency and quality. Our team offers advanced engineering services that include Design for Manufacturability (DFM), which ensures your designs are optimized for both production efficiency and cost-effectiveness. We also conduct mold-flow analysis to catch potential defects early, so your product is flawless from the start. And, with our deep knowledge of material selection, we can recommend the best thermoplastics for your specific needs, ensuring that your product is durable, functional, and cost-efficient.

Beyond that, with in-house tool management and maintenance, we ensure that your tools are always in top condition so you can avoid costly downtime. We also offer a variety of secondary operations, like painting, laser printing, and ultrasonic welding, to enhance the functionality and aesthetic appeal of your products. And whether you need sub-assembly or full-scale assembly, we integrate both electrical and mechanical components to streamline the process and improve quality.

Ready to Streamline Your Manufacturing Process?

Ferriot’s full-service contract manufacturing allows you to place multiple projects with one trusted partner, ensuring smoother operations, reduced costs, and higher-quality products. We specialize in providing customized solutions that meet the unique needs of each OEM we work with, from the initial design phase through to the final assembly.

If you’re looking for a reliable partner to help you bring your products to market faster and more cost-effectively, Ferriot is here to help. Contact us today to learn how we can support your next project with our full-service manufacturing capabilities.